Fagerhult Partners with Metals Company for Aluminum Recycling Success

Table of Contents

Expanding Environmental Sustainability in LED Lighting

In a significant move to enhance environmental sustainability within the LED lighting industry, Sweden’s leading lighting firm, Fagerhult, has systematically tackled the challenge of aluminum recycling. By joining forces with Hydro Extrusion Sweden AB, Fagerhult has launched an ambitious pilot project aiming to repurpose discarded aluminum luminaires into sustainable, high-quality materials.

Aluminum’s Role in Sustainability

Aluminum is highly recyclable, but maintaining its structural and functional integrity through repetitive recycling processes is challenging. “In collaboration with Hydro Extrusion Sweden, we are now exploring how we can close the loop,” emphasizes Niclas Thulin, head of sustainability at Fagerhult. This collaboration initially focuses on the Oslo office park Snarøyveien 30, owned by Norwegian Property, where the processing of discarded aluminum luminaires has commenced.

The Recycling Challenge

Standard recycling processes often degrade aluminum’s quality. This degradation can compromise the structural and functional properties necessary for reliable, eco-friendly luminaires. By maintaining the material’s integrity, Fagerhult aims to significantly advance the lighting industry’s sustainability goals.

The Pilot Project and Its Methodology

Nature of the Project

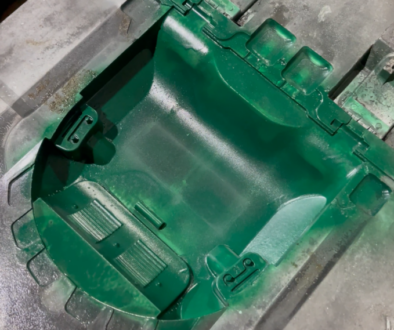

In this initiative, Fagerhult collected aluminum Notor luminaires from the Snarøyveien 30 office complex during its remodeling phase. These luminaires were then transported to Hydro’s recycling facility in Vetlanda, Sweden, where they underwent an extrusion process designed to retain the strength and durability of the aluminum.

Extrusion vs. Die Casting

Unlike die casting—which is often employed in secondary recycling processes and can produce weaker materials—extrusion typically yields stronger aluminum. “In this project, we wanted to ensure the qualities of the material by allowing the original producer to process the material again,” states Thulin, highlighting the importance of maintaining high material standards.

Outcomes and Insights

The pilot project successfully reclaimed 1,300 kilograms (1.43 U.S. tons) of aluminum, underscoring the process’s efficiency and effectiveness. Kristian Frisk, account manager at Hydro Extrusion, remarked, “The big gain is the insights we will take to future projects,” validating aluminum’s potential for near-endless recycling if processed correctly.

Broader Industry Trends

Fagerhult’s Broader Sustainability Impact

Beyond aluminum, Fagerhult is exploring various eco-friendly materials and sustainable processes, notably through its Italian brand, iGuzzini, which utilizes linen. This diversification points to a broader industry trend towards adopting sustainable innovations in material usage and manufacturing practices.

Other Industry Players

Competitors in the lighting industry like Glamox and Signify are also making significant strides. Glamox has incorporated recycled aluminum in its products, while Signify has ventured into the realm of 3D-printed luminaires, showcasing the diverse paths companies are taking towards eco-friendly production.

Validation of Sustainability Goals

Both Glamox and Signify have garnered third-party validation for their sustainability goals, setting an industry benchmark for achieving net-zero emissions. Their initiatives resonate with Fagerhult’s, reinforcing the collective industry movement towards greener practices.

Q&A Section

What is the significance of extruded aluminum in recycling?

Extruded aluminum maintains its properties better and is stronger compared to die-cast aluminum, making it a more sustainable choice in terms of durability and quality for recycling processes.

How much aluminum was reclaimed in the Fagerhult pilot project?

The project successfully reclaimed 1,300 kilograms (1.43 U.S. tons) of aluminum, demonstrating the effectiveness of their recycling initiative.

What other sustainable materials are being explored in the lighting industry?

Apart from aluminum, companies like Signify and Fagerhult’s iGuzzini brand are exploring materials such as 3D-printed components and linen, pushing for more sustainable manufacturing alternatives.

Conclusion

Fagerhult’s successful pilot project at the Snarøyveien 30 office complex in Oslo marks a significant advancement for both the company and the industry in sustainable production. By closing the loop on aluminum recycling, Fagerhult sets a precedent for future initiatives, reaffirming its commitment to a greener, more sustainable world.